How Does A Steam Turbine Work?

Introduction

Ever thought about how big power stations create electricity, or what makes huge ships move across the sea? At the center of these big jobs is an important and interesting machine called the steam turbine. So, how does this marvel of engineering work? It may seem like a tough question, but we can make it easier to understand. Think of it like a huge tea kettle that makes power. That’s a good start to understanding steam generators!

What is a Steam Turbine?

A steam turbine is a mechanical device that converts the thermal energy in steam into mechanical energy by rotating a rotor. This rotation can then be used to drive machinery like electric generators, pumps, or compressors. In essence, these steam turbine generators harness the energy from converted heat energy to produce rotational motion.

Steam turbines work a lot like a windmill you see today, but it uses the pressure of the steam to move instead of wind. It’s a machine that changes the heat energy in steam into a type of energy that makes things move, called mechanical energy. This mechanical energy is then used to make electricity. Modern steam turbines are important in places like large power plants, where they help produce the electricity we use every day.

The Basic Principal

The process of converting steam into mechanical power in a steam turbine is a sophisticated yet fundamental concept. It centers around the interaction between steam and a series of meticulously designed blades. These blades are strategically mounted on a shaft, a central rod that serves as the axis of rotation that rotate the turbine.

When a high-pressure flow of steam is directed onto these blades, it imparts its kinetic energy to them. This action causes the blades, and consequently the shaft, to rotate. This rotational movement is more than just mechanical motion; it is the critical element in the generation of power output.

The efficiency of this process is heavily reliant on the design of the blades and the quality of the steam. The blades are shaped to capture the maximum energy from the steam, converting heat and pressure into rotational force. This force is then harnessed and transferred to generate electricity or to drive other mechanical processes.

The spinning of the turbine shaft is a pivotal step in transforming the latent thermal energy of steam into usable mechanical energy. This transformation is a cornerstone in various applications, notably in electricity generation, where it plays a vital role in powering homes, businesses, and industries. The elegance of this system lies in its ability to efficiently harness a natural resource like steam for substantial power production.

Key Components of a Turbine

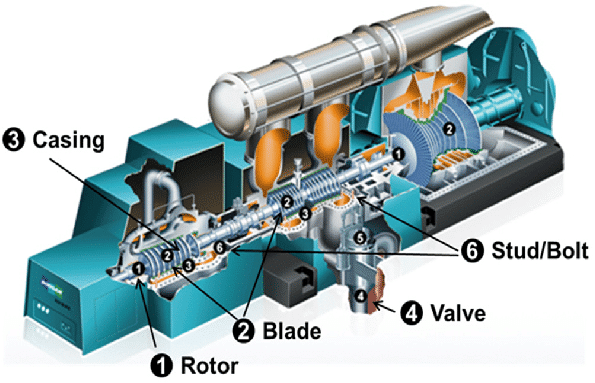

Blades

The blades in a steam turbine serve a critical function, similarly to the sails on a ship. They are expertly designed to capture the force and pressure of steam. As steam is funneled onto these blades and the steam expands, their precise angling and aerodynamic shape allow them to convert the steam’s thermal energy into kinetic energy and control the flow of steam, effectively transforming heat and steam pressure into mechanical motion.

Rotor

This component is the dynamic core of the turbine, essentially forming the backbone of the entire system. The rotor, to which the blades are attached, converts the force exerted by the steam onto the blades into rotational motion. It’s this rotation that is central to the power generation process, with the rotor’s speed and stability being critical factors in the turbine’s overall efficiency.

Casing

The casing of a steam turbine plays a vital role in ensuring operational safety and efficiency. It acts as a robust, protective barrier that encloses the high-pressure steam and the rotating blades. This containment is crucial, as it not only prevents the escape of steam but also maximizes the steam’s impact on the blades. The casing is designed to withstand extreme temperatures and pressures, ensuring the longevity and reliability of the turbine.

Bearings

Bearings are essential in maintaining the smooth operation of the rotor. Positioned at key points along the rotor, they reduce friction and wear, allowing for a seamless and efficient rotation. The bearings must be capable of handling the high rotational speeds and significant loads of the rotor while ensuring minimal energy loss. Regular maintenance of these bearings is crucial to prevent mechanical failures and to sustain the turbine’s optimal performance.

The Steam Cycle

The operation of a steam turbine is a fascinating interplay of pressure and temperature, fundamental to its turbine efficiency and effectiveness. The journey begins with the generation of steam in a boiler. Here, water is heated to extremely high temperatures under pressure, transforming it into steam. This steam, carrying high thermal energy, is then channeled into the condensing turbine.

Upon entering the turbine, the steam encounters the blades and the rotor. As it passes over these components, steam expands and cools, transferring its energy to the turbine blades. This transfer of energy causes the blades, and consequently the rotor, to spin, converting the thermal energy of the steam into mechanical energy. This conversion is the heart of the turbine’s operation, where the kinetic energy is harnessed to drive generators or other mechanical systems.

After imparting its energy, the steam’s journey is not yet over. It moves to the condenser, a key component where the steam is cooled and condensed back into water. This phase is critical as it converts the low-energy steam back into water, effectively resetting the cycle. The water is then returned to the boiler, ready to be heated again, thus continuing the cycle.

This continuous cycle of heating, expanding, cooling, and condensing is pivotal for the sustained operation of the steam turbine. Each stage is finely tuned to optimize the energy transfer and ensure efficient power generation. Understanding this journey of steam provides insight into the sophisticated engineering behind turbine technology and its crucial role in energy production.

Types of Steam Turbines

Impulse Turbines

The working principle of an impulse turbine is like the action of throwing a ball against a wall. In this type of turbine, high-pressure steam is directed onto the turbine blades in a manner similar to a jet hitting a surface. As the steam strikes the blades, it imparts its momentum to them, causing the rotor to which these blades are attached to turn. This action is much like the ball transferring its energy to the wall upon impact. In impulse turbines, the steam undergoes a significant drop in pressure as it passes through a nozzle before it hits the blades. This drop in pressure converts the steam’s thermal energy into kinetic energy, thereby propelling the blades and the rotor. The efficiency of impulse turbines lies in their ability to convert the high kinetic energy of steam into mechanical work.

Reaction Turbines

In contrast, reaction turbines operate on a principle akin to that of a jet engine. Instead of steam being directed at the blades from a nozzle, the steam flows through specially designed passages within the blades themselves. As the steam passes through these passages, it expands and accelerates, exerting a force on the blades. This force causes the blades, and thus the rotor, to spin. This process is continuous, with steam entering and exiting the blades, maintaining a constant flow. In reaction turbines, both the pressure and velocity of steam play a crucial role in generating motion. The design of the blades is key to ensuring that the steam imparts as much of its energy as possible, allowing for efficient energy conversion from the steam’s thermal and kinetic energy to mechanical energy.

Both impulse and reaction turbines are integral to the field of turbine technology, each with their unique design and operational characteristics. They are critical in applications requiring the conversion of steam energy into mechanical work, such as in power generation and various industrial processes. Understanding the differences in their operating principles is essential for selecting the appropriate turbine type for a specific application, ensuring maximum efficiency and effectiveness in energy conversion.

Energy Conversion Process

In the heart of a steam turbine, a transformative process occurs that can be likened to a kind of engineering magic. Here, the thermal energy carried by steam is ingeniously converted into mechanical energy. This pivotal conversion takes place as the rotor, a central component of the turbine, begins to spin. The steam, having been heated to a high temperature under significant pressure in a boiler, possesses a substantial amount of thermal energy. As it flows through the turbine, this steam exerts force on the blades attached to the rotor, causing it to rotate.

This rotational motion of the rotor is the crux of the turbine’s functionality. As the rotor spins, it drives the connected machinery, such as an electrical generator in power plants or the propulsion systems in maritime vessels. In the case of electricity generation, the spinning rotor turns the generator, which then converts this mechanical energy into electrical energy through electromagnetic induction. This electricity is then channeled into power grids, providing energy to homes, businesses, and industries.

Similarly, in marine applications, the mechanical energy produced by the spinning rotor is used to propel ships. This is typically achieved through a series of gears and shafts that transfer the rotational energy from the turbine to the ship’s propellers, pushing the vessel through the water.

The efficiency of this energy conversion process is a testament to the advanced engineering and design of steam turbines. It highlights the turbine’s ability to harness the power of steam effectively, transforming it into a usable form of energy. This process is not only a cornerstone in modern power generation but also a vital component in marine propulsion, underpinning the functionality of numerous industrial and transportation systems.

Applications of Steam Turbines

Power Generation

In the realm of electricity production, steam turbines stand as the backbone of most power plants, playing a pivotal role in transforming raw energy into a usable form. These turbines are integral in facilities ranging from traditional coal-fired power stations to nuclear reactors, and even in renewable energy plants like concentrated solar power systems. They work by converting the high-pressure steam generated in boilers into mechanical energy, which in turn drives generators to produce electricity. This electricity is then distributed through power grids, lighting up cities, powering industries, and energizing homes. The efficiency and reliability of steam turbines make them a cornerstone in the energy sector, essential for meeting the growing electricity demands of modern society.

Marine Propulsion

Steam turbines also play a crucial role in the maritime industry, propelling large ships across the world’s oceans. In this application, the mechanical energy produced by the turbine is used to drive the ship’s propellers. This provides a powerful and steady source of propulsion, enabling vessels such as cargo ships, cruise liners, and even some naval ships to navigate global waters. The durability and efficiency of steam turbines in converting thermal energy to mechanical motion make them ideal for long voyages, ensuring ships have the necessary power for their journeys.

Industrial Processes

Beyond power generation and marine propulsion, steam turbines are instrumental in various industrial processes. In sectors like manufacturing and refining, they are used to drive machinery and equipment. This includes applications in petrochemical plants, where turbines might power compressors and pumps, and in manufacturing facilities, where they can drive assembly lines or processing units. The versatility of steam turbines in these settings highlights their ability to adapt to different operational needs, providing a reliable source of mechanical or electrical power across a wide range of industrial applications.

Steam turbines are a linchpin in numerous critical areas. Their role in power generation, marine propulsion, and industrial processes underscores their importance in sustaining and advancing modern industrial and technological capabilities. Their efficiency, reliability, and adaptability make them an indispensable asset across various sectors.

Maintenance and Safety

Maintaining a steam turbine requires a meticulous and proactive approach, given the high-stakes environment in which these machines operate. Regular inspections are a critical aspect of this maintenance regimen. These inspections involve comprehensive checks of the turbine’s components, including blades, rotors, bearings, and seals, to identify any signs of wear, corrosion, or damage. Early detection of potential issues is key to preventing breakdowns and ensuring the turbine operates at optimal efficiency.

Lubrication plays a vital role in the upkeep of a steam turbine. The moving parts, especially the bearings and rotors, require consistent and appropriate lubrication to minimize friction and wear. Using the right type of lubricant and adhering to a scheduled lubrication program helps in prolonging the life of these components and ensures smooth operation.

Monitoring is another essential element of steam turbine maintenance. This involves continuous observation of various operational parameters such as temperature, pressure, vibration levels, and steam flow rates. Modern turbines are often equipped with sophisticated monitoring systems that provide real-time data, enabling operators to swiftly identify and address any irregularities. This constant vigilance helps in maintaining the efficiency of the turbine and reduces the likelihood of unexpected downtimes.

Safety is, without a doubt, the paramount concern in managing a steam turbine. The combination of high pressure and temperatures in a turbine’s operation presents inherent risks. Therefore, adherence to strict safety protocols and standards is essential. This includes regular safety training for personnel, ensuring all safety equipment is in good condition, and maintaining a clear protocol for emergency situations.

The maintenance of a steam turbine is a comprehensive process that demands attention to detail, regularity, and a deep understanding of the machine’s functioning. Through diligent inspections, proper lubrication, continuous monitoring, and a strong emphasis on safety, the longevity and efficient performance of a steam turbine can be significantly enhanced. This careful maintenance not only safeguards the turbine itself but also ensures the safety of the operators and the environment in which the turbine operates.

When maintenance isn’t enough and your turbine needs repair, Allied Power Group are the experts!

Future of Steam Turbines

As the global energy landscape shifts towards a more sustainable and renewable focus, the role and functionality of steam turbines are undergoing significant evolution. This transition is marked by advancements in efficiency and adaptability to new energy sources.

Traditionally, steam turbines have been a central part of fossil fuel-based power generation. However, with the increasing emphasis on reducing carbon emissions and utilizing renewable resources, these turbines are now being integrated into more environmentally friendly energy systems. For instance, in solar thermal power plants, steam turbines are used to convert the heat from the sun into electrical energy. This adaptation showcases their versatility and ability to operate with a variety of heat sources.

The drive towards greater efficiency in steam turbines has led to technological innovations. Modern turbines are designed to extract maximum energy from steam, thereby reducing waste and improving overall power plant efficiency. This involves enhancements in blade design, improvements in materials that can withstand higher temperatures and pressures, and more sophisticated control systems. These improvements not only contribute to the turbine’s performance but also play a significant role in reducing operational costs and environmental impact.

Furthermore, the integration of steam engine turbines with other renewable technologies, such as biomass and geothermal energy, further exemplifies their evolving role in the energy sector. By adapting to these diverse sources of heat, steam turbines are proving to be a resilient and versatile component in the transition towards a more sustainable energy future.

The adaptation of these turbines to new, more efficient designs, and their integration with a variety of renewable energy sources, reflect their ongoing relevance and critical role in the energy industry. As the world continues to shift towards renewable energy, the steam turbine remains a key player, continually adapting and evolving to meet the demands of this changing landscape.

Conclusion

Steam turbines stand as monumental achievements in engineering, playing a pivotal role in powering cities and driving the world’s maritime vessels. These machines epitomize the fusion of science and engineering, translating the raw power of steam into usable mechanical energy. Understanding how steam turbines operate allows us to truly appreciate these engineering marvels that form the backbone of modern power generation and marine propulsion.

In urban energy systems, steam turbines are integral to the functionality of power plants, converting thermal energy into electricity that lights up our cities and runs countless devices and appliances. They are the silent workhorses hidden behind the scenes, ensuring a steady and reliable flow of electricity to meet the demands of urban life.

In the maritime industry, steam turbines have revolutionized marine propulsion. These turbines power some of the largest ships traversing the oceans, from colossal cargo vessels to sophisticated cruise liners, providing them with the necessary thrust to navigate global waters. Their efficiency and reliability make them a preferred choice for long-distance sea travel.

Looking to the future, the prospects of steam turbines are closely tied with advancements in technology and a growing commitment to sustainability. As the world increasingly focuses on reducing carbon emissions and harnessing renewable energy sources, steam turbines are evolving to adapt to these new paradigms. Technological innovations are enhancing their efficiency and reducing their environmental impact. The development of turbines that can operate with a broader range of temperatures and pressures, as well as those compatible with renewable energy sources like solar and geothermal power, is indicative of this shift.

Ongoing research in materials science and thermodynamics is poised to yield even more efficient and robust steam turbines. These advancements promise to bolster the role of steam turbines in sustainable energy infrastructures, making them more adaptable and efficient in a rapidly changing energy landscape.

Steam turbines, with their unparalleled ability to convert thermal energy into mechanical power, continue to be indispensable in our world. Their role in powering cities and propelling ships is a testament to human ingenuity and engineering prowess. As we advance into an era focused on sustainability and innovation, the evolution of steam turbines remains a crucial aspect of our journey towards a more energy-efficient and environmentally conscious world.