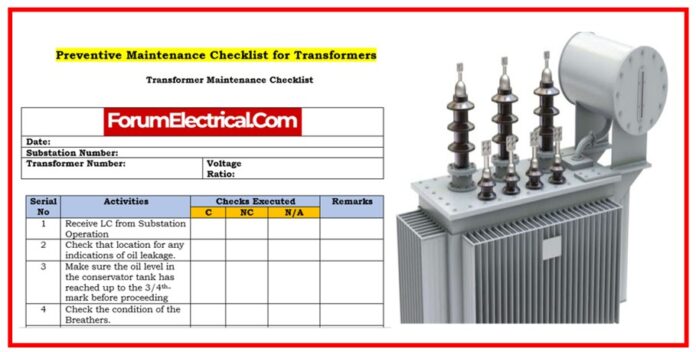

This checklist provides a high-level perspective on the many preventative maintenance activities that have to be carried out on transformers in a regular basis.

The particular routine of maintenance will change from transformer to transformer, based not only on the conditions in which it is functioning but also on the recommendations provided by the manufacturer.

It is essential to keep considering that the following is only a general check list.

The accurate maintenance procedures that need to be performed, as well as the frequency at which these functions need to be completed, will differ from transformer to transformer based on the operating parameters of that particular transformer.

Preventive Maintenance Protection

Any work on a transformer needs to be performed by qualified persons who are familiar with both the transformer in consideration and the operating procedures connected with it.

All preventative measures, including lockout & tagout processes, must be followed at all times.

Precautionary Measures

- Whenever a protection alert has gone off, do not energise without thoroughly examining the transformer and reactor.

- Do not restart the transformer reactor until the Buchholz gas has been examined.

- Do not re-energize the transformer reactor until all pre-commissioning checks have been completed. The outcomes must be equivalent to those at work.

- When the transformer is turned on, do not handle the off-circuit tap switch.

- Until the off% circuit tap switch handle is locked, the transformer is not powered.

- Do not leave the handle of the off circuit tap switch unlocked.

- Do not leave the secondary terminals outside the tank unprotected; instead, when they are connected to a load, connect them to the secondary lightning arrestor protection system.

- During the drying out of the transformer, do not allow the temperature of the filter machine to get over 0°C.

- Transformers which do not meet the requirements for paralleling should not be paralleled.

- Never utilise low-capacity lifter “acks on a reactor or transformer.

- The transformer reactor must not be moved while the bushings are attached.

- As to IS:6600, “do not overloading the transformer beyond the specified limits.”

- Do not alter the WTI & TI alarm & trip frequently settings. According to the site conditions, the setting must be made.

- In WTI and OTI, do not leave the red pointer beneath the black pointer.

- Do not allow any connections to get loose.

- Avoid tampering the safety circuits.

- Do not let the conservator oil level drop below the E level.

- Do not permit the bushings’ oil level to drop below the required level.

- It is forbidden to leave the marshalling bay doors unlocked.

- Do not turn off the heater in the marshalling area unless it needs to be regularly cleaned.

- To prevent dirt and dust buildup on bushings, they should be cleaned on a regular basis.

- Do not let unauthorised people into the area close to the transformer reactor.

- When the transformer or reactor is in use, do not leave the ladder unlocked, if one is provided.

- Do not alter the order in which the valves open to bring the standby pump & motor into the circuit.

- Do not turn on the water pump before turning the oil pump on.

- Do not use an indifferent pressure gauge that reads water pressure higher than oil pressure.

- Unless it complies with IS:335 requirements in full, do not mix the oil.

- Do not continue using subpar oil in the transformer reactor. When should the oil be utilised and how should it be handled right away? IS:1866 are met by BDV/ppm.

- Do not use pink silica gel any longer; instead, change or regenerate it right away.

- Do not leave a secondary CT terminal that is not loaded loaded open.

- Do not keep the transformer reactor in storage once it has reached equilibrium. It needs to be built and put into service as soon as possible.

- Do not leave the transformer’s reactor gas full at the location for an extended period of time.