Contents

What Are Air Brakes?

Cummins Wabco compressor

An air brake system contains compressed air that helps stop a vehicle when the brake pedal is pressed. The compressed air system relieves pressure on the springs, so the brakes can stop the wheels from spinning.

These systems are found on larger, heavy-duty vehicles, including:

- Buses

- Recreational vehicles

- Semi-trailers

- Trailers

- Trains

- Trucks

Standard passenger vehicles don’t require the heavy-duty braking power that these systems provide. Plus, the components in these systems cost more to manufacture.

How Do Air Brakes Work?

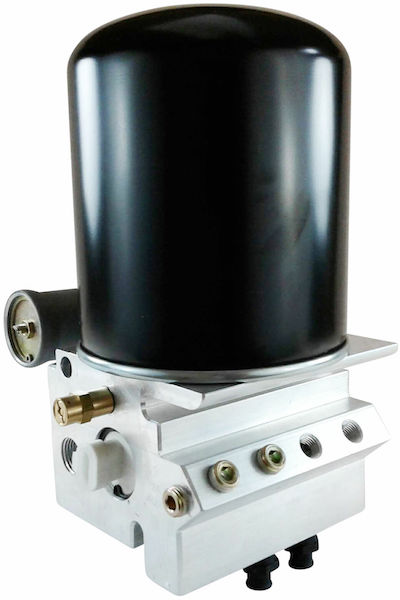

A pneumatic dryer

An air brake system has a two-stage compressor driven by the engine. The air enters the system from the ambient environment, and the system compresses the air, which is retained in a reservoir. An unloader valve opens when the reservoir pressure reaches a certain degree.

The vehicles’ wheels include brake chambers that contain a diaphragm. As air pressure is relieved, a spring pushes against the diaphragm. That force activates the brakes. All of these brake chambers are attached to the brake pedal. There’s also an air filter between the reservoir and the brake valve.

The system contain these main parts:

- Air compressor for building up and maintaining air pressure.

- Air dryer, typically installed between the reservoir and compressor, where it can remove moisture from the air.

- Brake chamber to transfer the compressed air force to mechanical linkage.

- Foot valve to draw compressed air from the reservoirs when braking is required.

- Reservoir tank to store compressed air.

- Safety valve with a spring-loaded ball design that prevents over-pressurization.

In basic terms, when you press the brake pedal, compressed air moves out of the reservoir to the chambers through the valve, causing the brakes to activate. Once you let off the pedal, the system returns to the original position, and pressure builds up, releasing the brakes from the wheels.

Difference Between Air vs. Hydraulic Brakes

Aside from stopping the vehicle, there are very few similarities between air and hydraulic systems. Here’s how each system is different.

- Hydraulic Brakes

Hydraulic oil is used to operate the brakes. The system’s main components include the oil reservoir, wheel cylinders, and master cylinder. It’s designed for light-duty vehicles, such as passenger cars, SUVs, and trucks. A hydraulic system isn’t nearly as powerful as air brakes. Engine power is not needed to run the hydraulic brakes, and the system is self-lubricating. - Air Brakes

Instead of hydraulic fluid, compressed air operates the brakes. It’s a more robust system, which is why it’s used on heavy-duty vehicles. Air brakes are not self-lubricating. Engine power is needed to run the air compressor. The main components include the chamber, brake valve, unloader valve, and compressor.

What is a Dual Air Brake System?

Most heavy-duty vehicles contain a dual air brake system designed to provide more safety. With the dual configuration, two systems are set up. Each one uses the same set of brake controls.

Because the two systems contain their own tank, lines, and hoses, there’s a backup in case of failure. One system runs the brakes for the front axle, while the other handles the back axle operation. However, one is considered the primary system, while the other is the secondary system.

Pros and Cons

How does it benefit commercial drivers to have an air brake system on the truck? Here are a few of the most important advantages:

- More effective at stopping heavy loads

- Easy to work on because brake parts are simple to locate

- Compressed air serves a dual purpose (can be used to inflate tires, etc.)

- Better braking control

- Reduced stopping time and distance

- Less wear and tear on parts

- Never run out of operating fluid because airflow is unlimited

- Requires less maintenance

Even with these benefits, an air brake system isn’t well-suited to every vehicle. Here are a few disadvantages:

- If leakage occurs, the brakes can lock up.

- It costs more to produce, making the vehicles more expensive.

- US commercial drivers require special licensing to operate a vehicle with air brakes.

- There’s a learning curve to operate them correctly.

People tend to swear by air or hydraulic systems, and heated discussions can arise about which is better. But, until you try them both, it’s hard to declare one better.

How Do You Adjust Air Brakes?

There are two types of adjusters: manual slack and automatic slack. Adjustment instructions depend on which one you work with.

A system with a manual slack adjuster is the most common type. Read the service manual for exact instructions, or follow these steps.

- Find the slack adjuster. The manual slack adjuster is a flat knob or handle on the side of the brake chamber. It’s usually on the left side.

- Tighten the adjuster. Jack up the truck. Press and hold the spring-loaded locking sleeve. Turn to tighten the slack adjustment.

- Adjust the bolt, but don’t push the pushrod from its chamber. Stop once it reaches its maximum stiffness. Leave room between the drum and the linings.

- Double-check the slack adjuster. Examine the distance from the exit point of the pushrod to the brake chamber face.

- Once you are done with the adjustment, lower your truck. When you start driving again, go slow and get a feel for the adjustments.

If your rig has automatic slack adjusters, there’s no reason to make manual alignment adjustments. However, to avoid problems, you should have a mechanic check the system every 25,000 to 50,000 miles.

Drivers of vehicles with air brakes are required by law to check the system before every trip. If you discover an issue, you should always contact a professional. Fixing these systems isn’t as simple as changing the pads.

Shop now for air brakes