Safe Isolation Procedure – A Thorough Step By Step Guide.

Introduction

Safe isolation is a task that needs to be undertaken for the safety of persons working on electrical installations and others who may be impacted by the process. Fundamental to the process is the person performing the safe isolation needs to be an electrically skilled person trained and competent to safely perform the complete process. The use of appropriate test equipment and ancillary equipment such as lock off devices is essential. This article seeks to raise the awareness for already competent persons required to carry out safe isolation and provides guidance on how this can be safely carried out. Every situation will be different in some way and additional provisions may need to be made depending on the outcome of a site-specific Risk Assessment and Method Statement.

The Law

The Electricity at Work Regulations 1989 (EAWR) (Ref 1) Regulation 16 Requires persons engaged in work on any work activity to be competent to prevent danger or injury, or to be under a degree of supervision. Is the person carrying out safe isolation competent to do so? The HSE Memorandum of Guidance on the EAWR (HSR 25) is available free from the HSE website.

Regulation 14 of the EAWR forbids any work on or so near any live conductor that danger may arise, unless it is covered with insulating material or unless it is unreasonable for it to be made dead. Does the safe isolation procedure require work on or near a live part? Does the procedure ensure safety in all cases? Does the person have evidence of their competency?

Regulation 13 of the EAWR requires adequate precautions to be taken to prevent electrical equipment, that has been made dead, in order to prevent danger from becoming electrically charged during that work, if danger may thereby arise. How will live parts made dead be prevented from becoming live after they have been isolated?

The Management of Health and Safety Regulations at Work Regulations 1999 (Ref 2) requires employers to carry out risk assessments. Is the person carrying out the safe isolation in possession of a Risk Assessment and Method Statement for the task? Do they have a permit to work and/or a permit to isolate?

Employers, employees and self-employed persons working on or near electrical installations must be made aware of the statutory duties placed on them by the EAWR.

Further guidance is available from the HSE such as Electricity at work Safe Working Practices (HSG 85) (Ref. 3) is available free from the HSE web site.

Preliminary Activities

Before starting work on site, the following activities will need to be undertaken.

- Agree a plan with the client on when and how the work will be carried out. Agree a Risk Assessment and Method Statement with the client. This should carefully consider for example the impact of the isolation on the safety of the persons on site, any impact on work processes, critical alarm systems, safety services and possible data loss from IT systems.

- The client should be asked to provide drawings and records of the installation. The authenticity of these documents should not be relied on but used for guidance only.

- Locate all sources of supply to the installation such as multiple incoming supplies, standby generators, UPS systems and UPSs. Careful consideration must be given to prevent these other sources of supply causing the isolated parts, proved dead, becoming live at some time after the safe isolation procedure. Power Factor correction units will need to be discharged or suitable period elapsed for them to self-discharge.

- Positively identify the correct circuit and point of supply that needs to be isolated.

- Select an approved voltage tester complying with British Standard BS EN 61243. The 2-pole tester should also meet the requirements of HSE GS 38. The Kewtech KT5 current and voltage tester meets, and exceeds, these requirements. Check the condition of the tester to ensure it is undamaged and in good condition. Verify that any internal battery is in a charged condition. A large number of voltages testers available require a potential difference between the probes to indicate the presence of a live supply. If, say in the case of a supply polarity reversal and the loss of an earth connection, these testers will not detect the presence of a live supply. The Kewtech KT5 tester will detect the presence of a live supply with contact with only one probe. The Kewtech KT5 also has a non-contact voltage detector built in, so enclosures such as external feed pillars and street furniture supply cabinets, can be tested to ensure they are not live through loss of the PME neutral before touching them. Multi-range instruments should not be used to prove dead as selection of the wrong range could be very dangerous. Neon screwdrivers should never be used and preferably be destroyed.

The Kewtech non-contact function verify a street furniture cabinet is dead.

Health and Safety

Take control of the intended work area and if required erect barriers and warning signs if required to exclude others from the work area. Ensure fire escape routes and exits are not blocked.

Preparation

Verify the voltage tester is functioning by testing it on a proving unit or known supply. Ensure a suitable lock off device, lock and a warning label is available for use.

Proving the voltage tester is functional of a Kewtech KT5 on the incoming side

of an isolated supply.

The Process

- Switch off the supply or circuit that is to be isolated.

- Lock off the means of isolation and display a warning notice to others not to interfere with the means of isolation.

- Use the voltage tester to test between earth and all live conductors to prove dead.

- Use the voltage tester to test between neutral and all line conductors to prove dead.

- Use the voltage tester between all combinations of line conductors to prove dead.

Proving an isolated supply is dead with a Kewtech KT5.

- Verify that there is no significant current flowing in main protective bonding conductors and earthing conductors using a current clamp meter. The Kewtech KT5 on the current range can be used for this purpose. Low levels of current flowing in protective conductors are normal under no fault conditions due to network circulating currents. Significant levels of current, several amps, may indicate the loss of the PEN conductor continuity on a PME system. If this is the case no attempt should be made to disconnect the protective conductor, no work should be undertaken on the installation and the DNO/DSO notified immediately.

Measuring current flowing in a main protective bonding conductor.

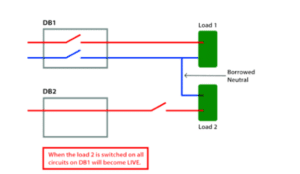

- If the means of isolation does not isolate the neutral and it is required to remove a neutral link, then before doing so use a clamp meter or the Kewtech KT5, to verify there is no current flowing in the neutral. This may be caused by a “borrowed neutral” from another supply. If there is no current flowing the neutral link can be removed using insulated tools. If there is any sparking as the neutral is disconnected this also indicates a borrowed neutral. If a borrowed neutral is suspected this must be traced before any work can be undertaken on the isolated circuit.

The hazard of a borrowed neutral.

- Reprove the voltage tester on a known supply or proving unit to verify it is still functioning correctly.

- Display warning notices on any equipment nearby that have not been isolated to warn of the hazard.

- A Permit to work can now be issued if applicable.

- It is important to recognise that the part of the installation that has been proved dead only at the moment of testing. Frequent verification that parts remain dead by testing using a good quality volt stick, such as the Kewtech Duo Voltstick, should be used before touching conductive parts to ensure they remain dead.

Reference Documents.

- Memorandum of guidance on the Electricity at Work Regulations 1989 (HSE HSR 25).

- Management of Health and Safety Regulations at Work Regulations 1999.

- Electricity at work Safe Working Practices (HSG 85).

- British Standard BS EN 61243-3:2014. Live Working Voltage Detectors- 2 Pole.